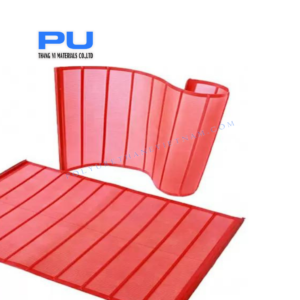

Polyurethane screens are used in many fields, such as mining mines, coal, etc. When mining mines, it is of great benefit to choose polyurethane screens.

Take measures to strictly control the coarse-breaking granularity and iron pinching. The installation of polyurethane screen can prolong the service life of the crusher.

The ore extracted from the mine is irregular and has a large grain size and cannot be directly ground into a ball mill. In order to reduce the cost of the ball mill, the ore must be crushed , and then put into the ball mill to dissociate. The dissociation phase before entering the ball mill is the crushing stage of the beneficiation. The general crushing process is: coarse breaking -> middle breaking -> screening, undersize after sieve -> ball mill; sieve after the sieve -> fine broken -> re-screening, which is the common three-stage closed circuit crushing process.

Jaw crusher or cone crusher is generally used for coarse crushing. Before crushing, the ore size must not exceed 650mm. In order to effectively control this size, crushers are installed with polyurethane screen that meet the crusher size. By controlling the particle size, it will reduce the resistance of the cracks, effectively protecting the jaws and preventing the crushing stop running.

With many years of experience in the application of high-end polyurethane materials, Thang Vi company understands the selection of polyurethane screens for a wide range of operating conditions and can help customers to shorten their material selection time. Welcome to order!